630.360.2548

Installing Sportscar Brake Kit.

Sportscar Brake Kit installation instructions:

WARNING:

Read these instructions completely before installation. The installation and assembly of all components should only be performed by qualified professionals with experience in the installation and assembly process of high performance automotive brake components / systems. These components will not function as intended if not installed or assembled properly to the correct specifications. It is the responsibility of the person installing or assembling any brake component to determine the suitability, and safety of the component. This product is intended for off-road use only.

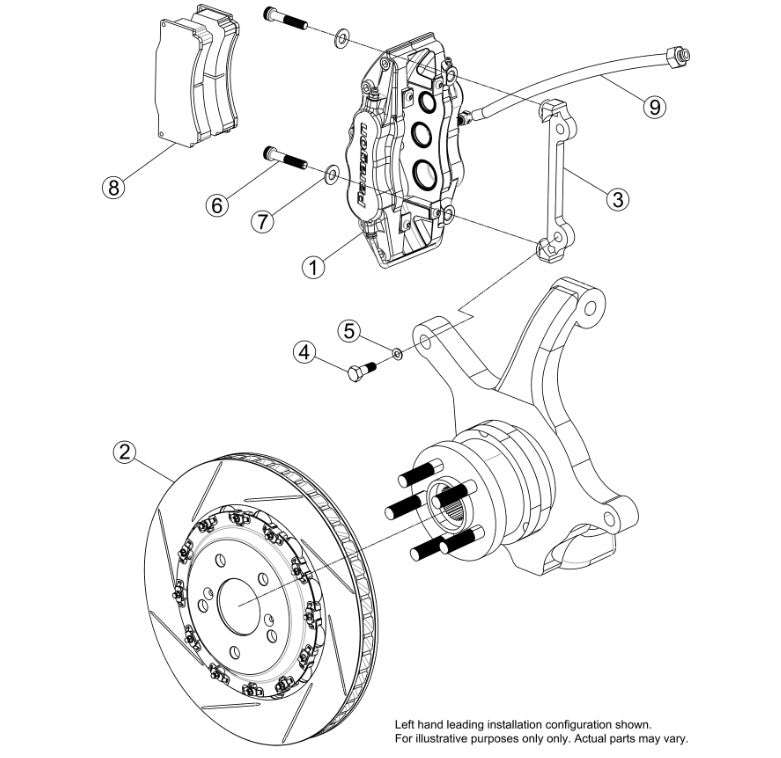

Exploded Diagram:

Item No. Description Qty

- Assembled brake caliper 2

- 2-piece rotor asembly 2

- Caliper mounting bracket 2

- Knuckle bolt (bracket to knuckle) 4

- Knuckle bolt washer 4

- Caliper bolt (caliper to bracket) 4

- Caliper bolt washer 1

- Brake pad (axle set) 2

- Brake line w/ copper washer and banjo bolt 4

Specific procedures may vary for each vehicle models. We recommend using the factory service manual to supplement these installation tips.

Step 1: Apply any rotor thermal paint, and caliper temperature indicator strips before installation (If applicable).

Step 2: Chock rear wheels. Raise vehicle and support with jack stands. Remove front wheel. NOTE: NEVER go underneath a vehicle only supported by a floor jack. A floor jack IS NOT a jack stand.

Step 3: Remove original brake line and caliper (hard line and/or rubber line, only remove what needs to be replaced).

NOTE: Have a rag and drain pan available to catch any brake fluid which leaks out. Brake fluid is highly corrosive and can damage painted/anodized finishes. Wipe off contaminated surfaces immediately. If brake fluid contacts the skin, wash contaminated skin immediately with water.

Step 4: Remove original rotor

Step 5: Remove original dust shield (If applicable).

NOTE: It is not necessary to remove the dust shield if there’s no interference. If the dust shield is not removed, you may need to bend or remove the ears of the shield near the caliper mounting ears. You may also need to bend the shield slightly inward near the lower ball joint and tie rod end for proper clearance.

Step 6: Install the caliper mounting bracket (3) to the knuckle using the knuckle bolts (4). Knuckle bolt washers (5) are not necessary on all applications. TORQUE TO FACTORY SPEC for your vehicle.

NOTE: The face of the bracket marked “ROTOR” should be towards the rotor. Torque the bolts to the original manufacturer’s specification. DO NOT OVER-TIGHTEN.

Step 7: Inspect and verify that the wheel hub mounting surface is completely flat and clean, and free from any rust, burrs, dents and abnormal wear; otherwise these surfaces should be reconditioned.

Step 8: Install new rotor assembly (2) onto wheel hub. Install three lug nuts (hand tight) to keep the rotor assembly in place. Check clearance between rotor and dust shield.

NOTE: Rotors utilize curved directional ventilation vanes. In order for the ventilation vanes to cool the rotors efficiently as designed, ventilation vanes must be facing the correct direction. Refer to Fig. 2 for the correct rotor rotation direction & placement. Use direction of ventilation vanes and slots as reference points.

Step 9: Determine the left and right hand side calipers (1), bolt the correct caliper to the bracket (3) using the supplied caliper bolts (6) and washers (7). Each caliper bolt requires one washer. Torque the bolts to 70 lbf-ft / 95 Nm. DO NOT OVER-TIGHTEN.

Refer to the marking at the back of the caliper for reference: LL = Left hand leading, RL = Right hand leading, LT = Left hand trailing, and RT = Right hand trailing.

Leading: caliper in front of axle. Trailing: caliper behind axle.

NOTE: Calipers are directional because of differential piston sizes. An arrow that denotes the direction of rotor rotation is marked at the back of the caliper. Rotor should always pass the smallest piston first. Refer to Fig. 3 for reference. When installed, the bleed screws are always positioned at the top of the caliper. Refer to Fig. 4 for reference.

Step 10: Temporarily install the wheel and torque the lug nuts to the original manufacturer’s specification. Ensure that the wheel rotates freely without any interference.

Step 11: Remove wheel. Using the supplied copper washers, install brake line banjo bolt into the caliper. Refer to Fig. 5 for reference. Leave the banjo bolt loose, so it can be correctly orientated during step 12 and 13.

Step 12: Connect the new brake line (9) to the vehicle, including the original mounting hardware and torque to the original manufacturer’s specification. Ensure the line is not twisted.

Step 13: Turn the steering wheel from full left lock to full right lock, ensure the line is not twisted, stretched, or interfere with other brakes, suspension, or chassis components in any position.

Step 14: Torque the banjo bolt to 18 lbf-ft / 25 Nm. DO NOT OVER-TIGHTEN.

Step 15: Remove anti rattle pad retainers, pad retaining bolts, and pad retaining tubes from caliper. Slide the pads (8) into the caliper. Reinstall anti rattle pad retainers, pad retaining bolts, and pad retaining tubes.

Torque the pad retaining bolts to 18 lbf-ft / 25 Nm. DO NOT OVER-TIGHTEN.

NOTE: Ensure the pads are not overhanging the outer edge of the rotor. The edge of the anti rattle pad retainer where the spring and block align should be facing the outside of the caliper.

Step 16: Repeat this process for the other side of the vehicle, then bleed the brakes.

Verifications:

Make sure the brake pads are secured in all calipers.

The bleeding procedure must be performed on all bleed screws in the system. During the bleeding procedure, check the fluid level in the reservoir frequently and make sure the fluid level does not fall below the minimum level marked on the reservoir. Torque the bleed screws to 12.5 lbf-ft / 17 Nm.

Remove any fluid in the area around the bleed screw thread and in the end of each bleed screw. Check the hydraulic system for leaks. Inspect for fluid leaks while system is under pressure.

Test the brake pedal before installing the wheels:

- If the brake pedal is spongy, bleed the system again

- If the brake pedal is initially firm, but then sinks to the floor, check the system for leaks

Step 17: Install wheels, check wheel clearance, and torque to factory specifications. Lower vehicle and remove chocks.

Step 18: Perform safety inspection before driving. DO NOT DRIVE ON UNTESTED BRAKES.

- Make sure the brake pedal is firm, and stop at least 1 inch from the floor under heavy load

- At low speed (< 5 mph), drive the vehicle with utmost caution and apply brakes hard several times whileturning from full left to full right. Repeat several times. Remove the wheels, inspect and ensure proper clearance between all components in the brake and suspension system. Check for fluid leaks

WARNING: Only perform safety check in a safe and controlled environment.

WARNING: Only perform bed-in procedure in a safe and controlled environment without any obstructions. We are not responsible for any damage, injury or death as a result of the bed-in procedure. Perform at your own risk. Start slowly at first with extra caution to make sure the brake system is functioning properly.

YOU MUST PROPERLY BED IN NEW ROTORS. This ensures smooth and consistent operation. Failure to bed in pads and rotors properly could result in shudder and substandard life and performance.

The purpose of bed-in procedure is to mate the brake pads with the rotors to ensure full contact, establish proper and consistent friction surface (transfer layer), and release the organic binding material (resin) held inside the pads during manufacturing process. With proper bed-in, excellent brake modulation, pad and rotor wear, and stopping power can be achieved. This process can also help minimize brake judder and rotor cracking.

NOTE: Avoid holding on the brake pedal during complete stops, which may lead to imprinting. Avoid ABS Intervention. Do not drag brakes. Block off brake ducts if necessary to allow optimal bedding-in temperature.

Step 1: While the vehicle is stationary, pump the brakes to ensure a firm pedal.

Step 2: Drive the vehicle with utmost caution and ensure the brake system is working properly.

Step 3: Applying moderate brake pressure, make 6 to 10 stops to 5 MPH (8 KM/H) from approximately 30 to 35 MPH (48 KM/H to 56 KM/H). After each stop to 5 MPH (8 KM/H), immediately accelerate back up to speed and repeat the process.

Step 4: Make 2 to 3 stops to 5 MPH (8 KM/H) from approximately 40 to 45 MPH (64 KM/H to 72 KM/H). After each stop to 5 MPH (8 KM/H), immediately accelerate back up to speed and repeat the process.

Step 5: Cruise at 45+ MPH (72+ KM/H) for 10 minutes to allow the brake system to cool.

Step 6: Inspect the rotor visually. Make sure there is an even layer of wear on the entire rotor surface.

Otherwise, repeat steps 3 to 6. The brakes may overheat quicker than expected, which may lead to glazing on the brake pads. Inspect rotors frequently. Do not apply emergency brakes right after bedding-in.

If you need any assistance, please contact technical support at support@alconkits.com

Disclaimer:

By virtue of the purchase and opening of the product sold the purchaser expressly acknowledges, understands and agrees to assume full responsibility post-sale. AlconKits is no longer liable for any cost for the servicing, repairs and are completely discharged of any resulting liability it may ensue through the use of the product. The purchaser agrees to take on all risks involved with the use of the product, whether it be from the quality, build, performance, maintenance of the product, or any other risks involved with the use of the product, or alongside the use of the product. The purchase agrees we are not responsible for any damage (consequential or otherwise) or any losses suffered, potentially or actually, for and-or from equipment failure or mal-performance after installation. Alconkits disclaims any implied warranty of merchantability or warranty of fitness for a particular purpose, including fitness of these systems, parts or equipment for racing or off-road use, and the buyer accepts this fully. ‘Racing or off-road use’ refers to the intended use of the product for off-road and racing use, neither of which any implied warranty of merchantability or warranty of fitness or satisfactory quality will be accepted. No warranty or representation is made to the product’s ability to protect the user from injury or death. The user assumes all risk, actually and potentially, whether material to the injury or not. The purchaser also expressly, by virtue of the purchase, agrees to exercise and rely upon their own skill and judgement in selecting the product and deciding it to be suitable for their intended use. Paragon warrants the brake rotors as delivered as free from defects in materials and or workmanship while in new, unused condition. Once the product has been mounted to vehicle and-or used in any way, the product is the responsibility of the owner.

Noise, Vibration, and Harshness (NVH):

High performance automotive components tend to create more noise, vibration and harshness when compared to OEM components. Most of our rotors utilize anti-rattle clips, but NVH is still possible. NVH related problems with the brake system can be caused by many factors. The customer is responsible for any noise, judder, vibration, and harshness with the brake system.

Anodized Aluminum Finish:

The calipers and hats in this kit are hard anodized. They are subject to corrosion when in contact with corrosive agents including brake fluid, certain types of wheel cleaner / soap, road salt, etc. Please exercise caution when the components are in contact with these substances.