Alcon Armored Brake Pads: Engineering Braking Confidence for Heavily-Upgraded and Armored Vehicles

Armoring a vehicle fundamentally changes the braking problem. Between ballistic panels, overlapping glass packs, and structural reinforcements, curb weight can climb by 30–50% with little or no increase in wheel diameter. Stopping the same chassis safely—without runaway rotor temperatures, long pedal, or premature pad fade—demands a very different pad compound and a system that can survive far higher thermal and mechanical loads. That is the design brief behind Alcon’s armored-vehicle brake systems and pad compounds. Alcon

Below, we dive into how Alcon’s armored brake pads are engineered, the technical tradeoffs involved, and what real-world benefits owners of armored SUVs, pickups, and specialty security vehicles can expect.

What makes “armored” brake pads different?

Duty cycle and thermal load

Armored vehicles generate far more kinetic energy for the same deceleration because of the higher gross vehicle weight (GVW). Alcon addresses this with pad materials that maintain stable friction at elevated temperatures and resist fade through repeated high-energy stops—conditions typical of convoy, pursuit, and emergency maneuvers. In complete armored kits tested on platforms like the Toyota Land Cruiser, Alcon reports large reductions in disc temperature rise and pad work rate versus stock systems, which directly reflects the pad compound’s ability to carry load without overheating. Alcon

Compound and friction stability

Alcon’s armored-vehicle pad compounds (e.g., AV1) are formulated for consistent friction and heat resistance so the pedal remains linear as temperatures climb. These compounds are built to keep μ (the friction coefficient) stable across a broad temperature window, preserving torque output and pedal feel during extended high-energy braking. Alcon Brake Kits

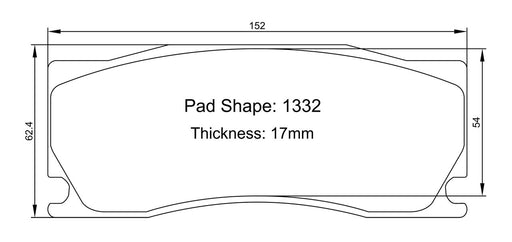

Increased pad area and heat flux management

Armored kits typically pair larger rotors with calipers and pad shapes that increase effective pad area. More area spreads heat flux, reduces localized temperatures, and slows wear—critical when GVW is far above stock. Alcon documentation highlights “increased pad area” as a core lever for lowering pad temperatures and extending life at armored weights.

System durability under harsh conditions

Survivability isn’t just about friction material. Alcon combines ductile-iron calipers (for stiffness and impact resistance), high-temperature seals, push-back springs (to control drag and wear off-road), and corrosion-resistant finishes. These measures keep the caliper/pad interface stable and reliable in dirty, hot, or corrosive environments common to security fleets. Alcon

How Alcon translates motorsport tech to armored service

Alcon’s background in top-tier motorsport influences pad and system design: larger thermal mass, efficient energy dissipation, and materials optimized for repeated high-energy braking. Trade publications covering Alcon’s armored programs consistently emphasize higher friction materials, larger discs, and caliper features that reduce hydraulic losses—technology migrating directly from racing to defense/security vehicles. Army Recognition - The BRAKE Report

Real-world platform examples

- Toyota Land Cruiser (LC200/LC300) armored kits: Alcon cites up to a 45% reduction in disc temperature rise, ~42% reduction in pad work rates, and ~10% increase in available brake torque versus stock standard-duty systems—key indicators that the pad/rotor/caliper package can safely handle armored weights with less fade and effort. Alcon+1

- Ford F-550/F-450 armored duty: Heavy-duty kits pair high-friction pads with larger pad area to cut temperatures and extend life at high GVW—particularly relevant to up-armored rescue, utility, and dignitary transport trucks. Alcon USA

Selecting Alcon armored pads: practical guidance

- Match pad compound to mission profile. Continuous urban stop-and-go with frequent high-energy stops favors the highest thermal stability. Occasional emergency stops with highway cruising may allow slightly faster warm-up characteristics. (Look for AV1 or equivalent armored compounds in Alcon applications.) Alcon Brake Kits

- Prioritize system balance. Pads do their best work when paired with the correct rotor mass/diameter and caliper stiffness. If you’re running armored weight on stock-diameter rotors, pad temperatures will spike sooner; a full Alcon armored kit optimizes each component to prevent that. Alcon

- Inspect more often. Even with increased pad area and robust materials, armored service is punishing. Build inspection intervals around GVW and duty—don’t assume stock maintenance schedules apply. (Alcon’s armored pages highlight the unique demands and the need for properly engineered solutions rather than routine replacements.) Alcon

Benefits owners actually notice

- Shorter, repeatable stops at weight due to high, stable μ and torque consistency. Alcon

- Lower likelihood of fade during back-to-back high-energy stops thanks to compound and increased pad area.

- Longer service life relative to non-armored pads in the same application because of reduced pad work rates and thermal control. Alcon

- More confidence off-road from caliper/pad hardware designed to manage contamination and heat in harsh environments. Alcon

FAQs: Alcon Armored Brake Pads & Sourcing

Q1: What exactly are “armored” brake pads—are they just a firmer compound?

A: No. Armored pads are part of an engineered system for high-GVW vehicles. Compounds like Alcon’s AV1 are formulated for high thermal stability and consistent friction. They’re used alongside larger pad geometries, robust calipers, and high-mass rotors to cut temperatures and maintain torque at weight. Alcon Brake Kits

Q2: Can I run Alcon armored pads on stock rotors and calipers?

A: In many cases, armored-duty pads are offered within matched Alcon big-brake kits for a reason: pad performance depends on rotor size/mass and caliper stiffness. Mixing armored pads with undersized stock hardware limits the benefit and can still lead to elevated temperatures. The safest route is a complete armored kit where pads, rotors, and calipers are sized for your GVW. Alcon

Q3: How do Alcon’s armored pads affect pedal feel?

A: Properly matched, you’ll typically get a firmer, more linear pedal because the compound maintains friction as temperatures climb and the caliper design resists flex and rollback. Alcon’s armored kits report reduced pedal effort versus stock in like-for-like tests, which you feel as confident initial bite without going long. Alcon

Q4: Are there measurable performance deltas versus stock brakes?

A: Yes. On armored LC200 applications, Alcon publishes up to 45% less disc temperature rise and ~42% lower pad work rates, with ~10% more available brake torque—direct evidence of improved thermal control and stopping capability at weight. Alcon

Q5: Where can I buy genuine Alcon armored pads and get platform-specific guidance? Why Alconkits?

A: Alconkits is an official Alcon distributor specializing in both performance and armored/off-road systems. The site lists armored-system pads by platform (LC200/LC300, F-550, Patrol, Defender, etc.) and offers technical support plus free shipping on brake kits within the continental USA—useful for fleet procurement. Their catalog and support pages are organized by make/model and caliper type, which simplifies selecting the correct armored pad geometry and compound. Alcon Brake Kits

Q6: Do Alcon armored pads require special bedding-in?

A: Follow Alcon’s and the distributor’s bedding procedures for the specific compound. Proper bedding stabilizes the transfer layer, achieving the pad’s intended μ and minimizing judder during high-energy stops. (Consult the support/tech sections where your kit is listed.) Alcon Brake Kits

Q7: Are there armored-pad options for heavy-duty pickups like the F-450/550?

A: Yes. Alcon offers armored front kits and matching high-temperature pad sets for these platforms, designed to increase pad area and stopping power at high GVW.

Q8: Who uses Alcon’s armored solutions?

A: Alcon’s armored kits are used globally by armoring companies and security fleets; media coverage also notes adoption by entities such as the UN and other defense/security customers for high-GVW applications. Defense Advancement

Bottom line

If you’ve added serious weight to a platform—LC200/300, Patrol, F-450/550, Defender, and beyond—you need more than a “heavy-duty” street pad. Alcon’s armored brake pads, in concert with properly sized rotors and calipers, deliver stable friction, lower temperatures, and repeatable stopping at weight. For verified, platform-specific fitment and support, Alconkits provides official Alcon armored pads and kits with the logistics and tech help that armored operators value. Alcon Armored